Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Senior Content Specialist | Updated On - May 12, 2022

Hydraulic machines are the machines or tools that operate using fluid power. A great amount of electricity is transferred through hoses and little tubes in these machines. The fluid is passed throughout the machine to motors and hydraulic cylinders where it is pressurized before being sent to end effectors via control valves and tubes. The hydraulic system is similar to pneumatic systems as it is also based on Pascal's law which asserts that any pressure applied to a fluid inside a closed system would be transmitted equally everywhere in all directions. Instead of a compressible gas, a hydraulic system uses an incompressible liquid as its fluid.

Read More: Mechanical Properties of Fluids

| Table of Content |

Key Terms: Hydraulic machines, pressure, energy, force, Pascal`s Law.

[Click Here for Sample Questions]

Breakers, also known as hydraulic brakes, are a braking mechanism arrangement in which appropriate brake fluid is utilized to transfer pressure from the control mechanism to the brake mechanism. Automobile hydraulic brakes function on the same principle. When we apply a small amount of effort to the pedal with our foot, the master piston moves inside the master cylinder and the pressure created is communicated through the brake oil which acts on a larger piston. A strong force is applied to the piston which is pushed down, expanding the brake shoes against the brake lining. We can observe that a modest force on the pedal results in a huge retarding force on the wheels in this way. The hydraulic brake system has the advantage that the pressure applied by pressing a pedal is distributed evenly among all cylinders which are normally coupled to the four wheels resulting in equal braking effort on all four wheels.

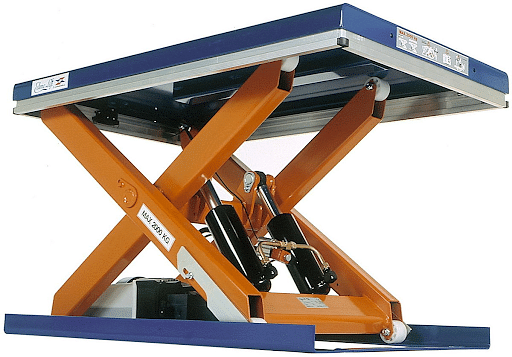

Hydraulic Lift refers to an elevator powered by fluid pressure generated by a suitable fluid. It is commonly used in service shops and garages to raise automobiles. A hydraulic lift consists of two pistons that are separated by a liquid-filled gap. A piston with a tiny cross-section A1 is employed to exert a force, of say F1, on the liquid immediately. The pressure, given by P=F/A, is passed via liquid to the larger cylinder which is then connected to a larger piston with an area A2, resulting in an upward force given by PxA2.

Read More:Units of Pressure

F2 = P x A2= FA1FA1 x A2

Thus, we can state that the piston can hold a large force such as the weight of a car or truck that is parked on the platform. The platform can be moved up or down by altering the force at the A1 area. As a result, we can say that the applied force has been increased by a factor of A2/A1, where A2/A1 is the overall mechanical advantage of the device.

Hydraulic Lift

Read More: Bulk Modulus

Hydraulic Jacks

Read More: conservation of energy

[Click Here for Sample Questions]

Read More: Stress and Strain

Question: How do hydraulic machines work? (1 Mark)

Question: What are some of the hydraulic systems' drawbacks? (1 mark)

Question: Explain the benefits of hydraulic systems. (1 mark)

Ques: What characterizes a hydraulic machine? (2 marks)

Ques: Compressed air produces a force F1 on a tiny piston with a radius of 5.0 cm in a car lift. This pressure is transferred to a 15-cm-radius second piston. Calculate F1 if the mass of the car to be raised is 1350 kg. What is the level of stress required to complete this task? (g = 9.8 milliseconds-2) (2 marks)

July 25, 2022

The service life of various hydraulic valves in the hydraulic support is very low. The way and solution for solving the problem abroad is to improve the filtration precision of the system and improve...

In this paper, we will analyze the last cause of the failure of the hydraulic valve in the future: cavitation. In this paper, we will analyze the last cause of the failure of the hydraulic valve in...

BWCB insulation gear pump motor high temperature reasons and countermeasures analysis 1, cause analysis (1) motor power, large operating current, large heat. (2) The fan speed is low, the wind...

Gear oil pumps are mainly used in the transfer, oil pressurization, fuel injection, etc. of oil media in chemical, petroleum, mining, metallurgy, power station and other industries, as well as in the...

Email to this supplier

July 25, 2022

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.