Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

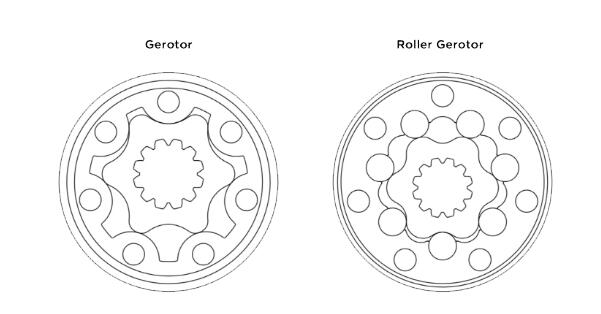

Orbit Hydraulic Motor: The ring gear is fixedly connected to the housing, and the oil entering from the port pushes the rotor to revolve around a center point. This slowly rotating rotor drives the output through a splined shaft into a Hydraulic Orbital Motor. After the introduction of this initial orbitl motor, after decades of evolution, another concept of the motor began to form. This motor has a roller mounted in the built-in ring gear. The motor with roller provides high starting and running torque, and the roller reduces friction,which increases efficiency even at very low speeds and produce a stable output. By changing the direction of the input and output flow, the motor is quickly reversed and produces equivalent torque in both directions. Each series of motors has a variety of displacement options to meet a variety of speed and torque requirements.

The hydraulic orbit motor is a small low-speed high-torque hydraulic motor with one-axis flow-setting insert and rotor pair.

The advantages are as follows:

1. Small in size and light in weight, its outer dimensions are much smaller than other types of Hydraulic Motors of the same torque.

2. wide range of speed, stepless speed regulation, the lowest stable speed up to 15 rev / min, easy installation,low investment costs.

3. It can be used in series in the hydraulic system, or it can be used in parallel.

4.the rotation inertia is small, easy to start under load, both forward and reverse can be used, and there is no need to stop when commuting.

hydraulic orbit motors are widely used in agricultural, fishing, light industry, lifting and transportation, mining, engineering machinery and other mechanical slewing mechanisms.

Examples of foreign applications of orbital hydraulic motors:

1. Agricultural use: various combine harvesters, planters, rotary tillers, lawn mowers, sprayers, feed mixers, ground drilling machines.

2. Fishing: use the net machine.

3. Light industrial use: winder, textile machine, printing machine, business washing machine.

4. Construction industry: road roller, cement mixer, sweeping vehicle.

Second, the structure and performance characteristics

The orbital hydraulic motor is an integral part of the output shaft and the valve, and the gear-type stator and rotor sub-cycloid hydraulic motor. The specific structure is shown as below

Main features:

1. Adopting end face distribution and axial flow distribution, the structure is simple and compact, and the flow matching precision is high;

2, using the insert stator and rotor pair, high mechanical efficiency, long life with high pressure operation;

3, the use of double-corner ball bearings, can withstand large radial and axial loads, low friction, high mechanical efficiency.

4. Advanced flow distribution mechanism design, featuring high flow matching precision and automatic wear compensation.

5, the motor can be used in series and parallel, when connected in series should be connected to the external drain.

6, using tapered roller bearing support design, with a large radial load capacity, so that the motor can directly drive the working mechanism.

More than 7 types of flanges, output shafts, oil ports, etc.

Third, the operation notes

(1) Check all components of the hydraulic system correctly before operation, and add oil to the specified height through the filter.

(2) Start the operation for 10 to 15 minutes without load, and perform exhausting, foam in the fuel tank, noise in the system, and stagnant motor cylinders to prove that there is air in the system.

(3) After removing the air, fill up the fuel tank, and then gradually increase the load to the motor until the maximum load, observe whether there are abnormal phenomena, such as noise, oil rise and oil leakage.

(4) Replace the oil by running for 50 hours, and replace it according to the maintenance rules.

(5) If it is not a motor failure, please do not disassemble it easily.

Fourth, disassembly and assembly

When the hydraulic motor fails to be disassembled, please pay attention to the following:

(1) Do not touch the joint surface when disassembling. If there is a bump, it needs to be trimmed before assembly.

(2) Wash all parts with gasoline or kerosene before assembly. Do not use cotton yarn or rag to scrub the parts. Apply brush or silk cloth. Do not immerse the rubber ring in gasoline. After the motor is installed, add 50~100ml of hydraulic oil to the two ports before installing the machine, and rotate the output oil. If there is no abnormality, install the machine.

(3) In order to ensure the correct rotation direction of the motor, attention should be paid to the positional relationship between the rotor and the output shaft.

(4) The back cover bolts must be tightened diagonally, and the tightening torque is 4~5 kg force·meter.

July 25, 2022

The service life of various hydraulic valves in the hydraulic support is very low. The way and solution for solving the problem abroad is to improve the filtration precision of the system and improve...

In this paper, we will analyze the last cause of the failure of the hydraulic valve in the future: cavitation. In this paper, we will analyze the last cause of the failure of the hydraulic valve in...

BWCB insulation gear pump motor high temperature reasons and countermeasures analysis 1, cause analysis (1) motor power, large operating current, large heat. (2) The fan speed is low, the wind...

Gear oil pumps are mainly used in the transfer, oil pressurization, fuel injection, etc. of oil media in chemical, petroleum, mining, metallurgy, power station and other industries, as well as in the...

Email to this supplier

July 25, 2022

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.