Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

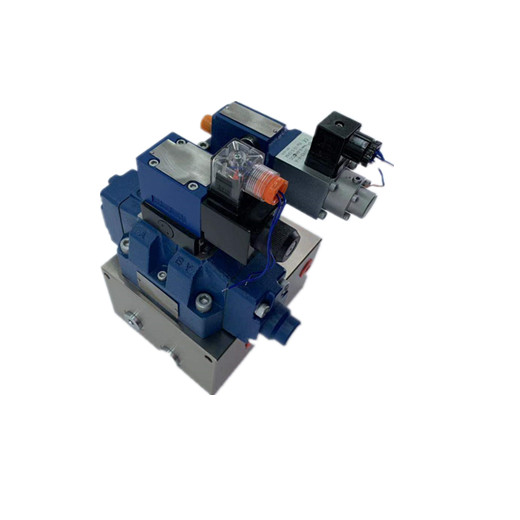

GRH designs and manufactures Hydraulic Valves for Tunnel boring machine, including propelling valve manifolds, Proportional Valve, pressure adjustment valve manifolds, directional valve manifolds, etc.

To meet the requirement of the earth surface level variation during tunnel boring, electro-hydraulic proportional push system with flow-pressure control, theoretical analysis and simulation of this push system are carried out. The use of GRH valves can improve the stationary control accuracy of the electrohydraulic proportional velocity regulating valve significantly.

On tunnel boring (TBM) machines, there are multiple hydraulic systems that control numerous functions. These hydraulic systems must operate with precise control and be reliable during operation deep underground.

Reliable solutions for Tunnel Boring Machines Cutterhead drive, propelling, steering and support functions. There are many operations and functions that need to work smoothly and reliably on a tunnel boring machine for efficient and safe operations. All of these actions have to use the right valve manifolds.

An electro-hydraulic control system for the thrust speed control in TBM was introduced by GRH and its dynamics model was established. An internal intelligent controller was then designed based on the regulation principles for improving effects in thrust speed control. GRH valves for TBM provides a possible new way for thrust hydraulic system of TBM, and also extend the applications for internal intelligent control. Meanwhile GRH also provide you with lubrication pump , Gear Pumps, as well as Flow Dividers for TBM.

July 25, 2022

The service life of various hydraulic valves in the hydraulic support is very low. The way and solution for solving the problem abroad is to improve the filtration precision of the system and improve...

In this paper, we will analyze the last cause of the failure of the hydraulic valve in the future: cavitation. In this paper, we will analyze the last cause of the failure of the hydraulic valve in...

BWCB insulation gear pump motor high temperature reasons and countermeasures analysis 1, cause analysis (1) motor power, large operating current, large heat. (2) The fan speed is low, the wind...

Gear oil pumps are mainly used in the transfer, oil pressurization, fuel injection, etc. of oil media in chemical, petroleum, mining, metallurgy, power station and other industries, as well as in the...

Email to this supplier

July 25, 2022

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.