Table of Contents

What is Gear Motor | Working , Diagram , Advantages ,Range

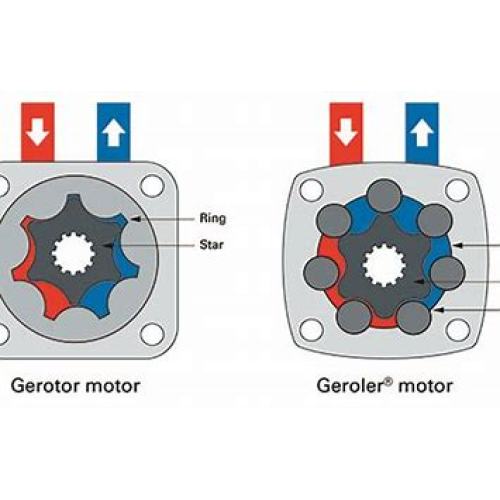

A gear motor develops torque due to hydraulic pressure acting against the area of one tooth. There are two teeth trying to move the rotor in the proper direction, while one net tooth at the center mesh tries to move it in the opposite direction. In the design of a gear motor, one of the gears is keyed to an output shaft, while the other is simply an idler gear. Pressurized oil is sent to the inlet port of the motor.

Pressure is then applied to the gear teeth, causing the gears and output shaft to rotate. The pressure builds until enough torque is generated to rotate the output shaft against the load. The side load on the motor bearing is quite high, because all the hydraulic pressure is on one side. This limits the bearing life of the motor. Schematic diagram of gear motor is shown in Fig.

Read also : What is Hydraulic Motor or Rotary Actuator | Types , Application

gear motor diagram

gear motor diagram Most of the gear motors are bidirectional. Reversing the direction of flow can reverse the direction of rotation.As in the case of Gear Pumps, volumetric displacement is fixed. Due to the high pressure at the inlet and low pressure at the outlet, a large side load on the shaft and bearings is produced. Gear motors are normally limited to 150 bar operating pressures and 2500 RPM operating speed. They are available with a maximum flow capacity of 600 LPM. The gear motors are simple in construction and have good dirt tolerance, but their efficiencies are lower than those of vane or piston pumps and they leak more than the piston units. Generally,they are not used as servo motors.Hydraulic Motors can also be of internal gear design. These types can operate at higher pressures and speeds and also have greater displacements than external gear motors.

Advantages of Gear Motors

The gear motors are simple ill design, and very cheap in cost.

Disadvantages of Gear Motors

- Gear motors are subjected to relatively high internal leakage. Therefore, they are not suitable for high torque, low speed applications.

- The high pressure at the inlet, coupled with the low pressure at the outlet, generates very high bearing loads.

Ranges

The gear motors are available for peak operating pressures upto about 125 bars, with rated capacities upto 10 Lps, and maximum speeds of about 3000 rpm.